Safety First: A Comprehensive Guide to Emergency Evacuation in Industrial Buildings

In the heart of Apex Manufacturing, safety officer Johnathan Reed diligently reviewed reports when a piercing siren shattered the routine.

Grabbing his safety vest and hard hat, Johnathan bolted out of his office, the urgency of the situation propelling him forward. As he raced through the corridors, his mind raced with possibilities – a chemical spill, a malfunctioning piece of equipment, or worse, a fire raging out of control.

With adrenaline fueling his actions, he raced to the emergency station, activating alarms and issuing evacuation orders.

Guiding his colleagues with calm authority, Johnathan led them to safety as emergency crews arrived.

As Johnathan settled back into his chair, a sense of accomplishment washed over him. The seamless execution of the emergency evacuation was not just luck—it was the result of meticulous planning and preparation.

You can be a hero like Johnathan too!

In the realm of industrial management, there are few responsibilities as paramount as ensuring the safety and well-being of all individuals within your facilities.

In this blog, we embark on a journey through the intricacies of emergency evacuation within industrial settings. From comprehending the unique challenges posed by industrial environments to implementing robust protocols for workplace safety and managing your company’s reputation, our aim is to equip you with the knowledge and insights necessary to make informed decisions regarding emergency preparedness.

Decoding Emergency Evacuation: A Primer for Industrial Settings

In industrial settings, several unique hazards pose risks to the safety and well-being of workers and the surrounding environment. These hazards can vary depending on the type of industry, processes involved, and materials handled.

Here are some common hazards found in industrial settings, along with the type of accidents they can lead to and special requirements for emergency preparedness:

| Type of Hazard | Type of Accident | Common Causes | Emergency Preparedness Measures |

| Chemical Hazards | Fires, explosions, toxic gas exposure, chemical burns | Chemical spills, leaks, releases, accidental mixing of incompatible chemicals | Material Safety Data Sheets (MSDS), implementing spill containment and cleanup procedures, providing appropriate PPE for workers |

| Fire and Combustible Hazards | Fire, explosions | Ignition of flammable materials, such as fuels, gasses, dust, or combustible liquids, electrical faults, hot work operations | Install fire detection and suppression systems, detailed emergency evacuation plans, regular evacuation drills |

| Mechanical Hazards | Crash injuries, amputations, entanglements, falls from height | Accidents involving machinery and equipment, malfunctioning or improperly guarded machinery | Regular maintenance, inspection, and safety checks of machinery, lockout/tagout procedures, knowledge emergency response protocols |

| Electrical Hazards | Electrical shocks, burns, electrocution, electrical fires | Contact with live wires, faulty equipment, overloaded circuits, short circuits, electrical arcing | Proper installation, grounding, and insulation of electrical equipment, training on electrical safety practices |

| Confined Space Hazards | Asphyxiation, suffocation, or entrapment | Hazardous atmospheres containing toxic gasses or low oxygen levels | Implement strict confined space entry procedures, use of proper safety equipment, detailed emergency response plans |

Along with the different types of hazards, the complexity of layout and infrastructure also poses a challenge for emergency evacuation in industrial buildings.

Industrial buildings come in various shapes and sizes, ranging from sprawling manufacturing plants to compact warehouses. Narrow corridors, high ceilings, and labyrinthine pathways may pose obstacles during an evacuation. All these factors need to be taken into account while preparing the evacuation plan for your company.

Counting the Cost: Assessing the Effects of Emergencies on Company Success

Industrial environments are characterized by their dynamic nature. From changes in production processes to the introduction of new materials, staying abreast of these dynamic risks is essential for effective emergency preparedness.

Which is why emergency preparedness should be a cornerstone of any company’s broader risk management strategy for several compelling reasons:

- Protecting People: The foremost priority of any organization should be the safety and well-being of its employees, customers, visitors, and stakeholders.

- Minimizing Losses: Emergencies such as fires, natural disasters, or industrial accidents can result in significant financial losses for companies, including property damage, operational disruptions, and potential legal liabilities.

- Maintaining Continuity of Operations: By identifying critical functions, implementing contingency plans, and maintaining redundant systems, companies can reduce downtime and maintain business continuity, thus preserving revenue streams and customer trust.

- Preserving Reputation and Brand Integrity: How a company responds to emergencies can have a lasting impact on its reputation and brand integrity. Prompt and effective emergency response can enhance public trust and confidence in the organization, while a mishandled crisis can lead to reputational damage and loss of customer loyalty.

- Enhancing Stakeholder Confidence: Investors, shareholders, customers, and other stakeholders expect companies to demonstrate sound risk management practices, including preparedness for emergencies. By proactively addressing potential risks and demonstrating readiness to respond to emergencies, companies can enhance stakeholder confidence and maintain positive relationships with key stakeholders.

Building Resilience: Preparing Your Company for the Unexpected

In the realm of emergency preparedness, the old adage holds true: “By failing to prepare, you are preparing to fail.” This sentiment resonates profoundly in industrial settings, where the stakes are high, and the margin for error is slim.

Here’s how industrial organizations can effectively prepare before an emergency strikes:

Conduct Comprehensive Risk Assessments

Before drafting evacuation plans or implementing occupational safety measures, it is imperative to conduct comprehensive risk assessments tailored to the specific hazards present in the industrial environment. Identify potential sources of emergencies, such as chemical storage areas, machinery, or electrical systems, and assess the likelihood and potential impact of each scenario.

Develop Robust Evacuation Plans

Based on the findings of risk assessments, develop robust evacuation plans that outline clear procedures for responding to emergencies. These plans should include designated evacuation routes, assembly points, and protocols for alerting and guiding individuals to safety.

Ensure that evacuation plans are easily accessible, well-communicated, and regularly reviewed and updated as needed.

Provide Adequate Training and Education

Effective emergency preparedness hinges on the knowledge and readiness of individuals within the organization. You can use visual aids like safety animation and videos to provide comprehensive training and education to employees on evacuation procedures, emergency response protocols, and the proper use of fire fighting safety equipment.

Apart from the toolbox topics, you should also include practical exercises and drills to reinforce learning and familiarize individuals with evacuation routes and procedures.

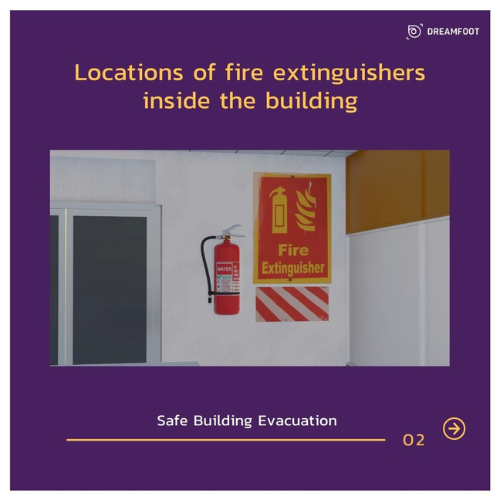

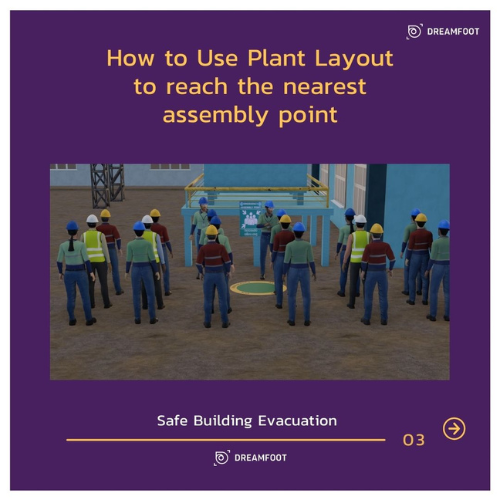

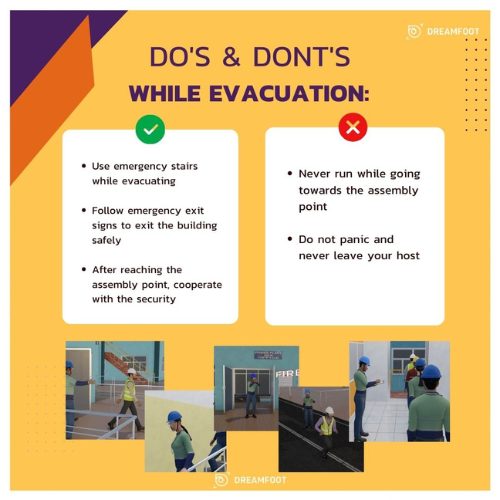

The visual aids like 3D animated safety videos and the practical exercises help you convey vital information such as:

- Location of fire extinguishers inside the building

- How to use plant layout to reach the nearest assembly point

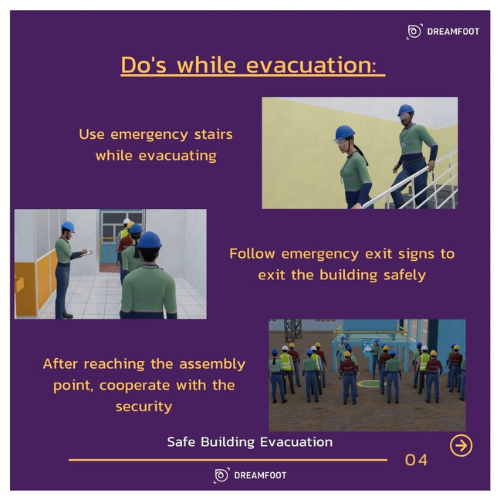

- The basic dos and don’ts during the evacuation

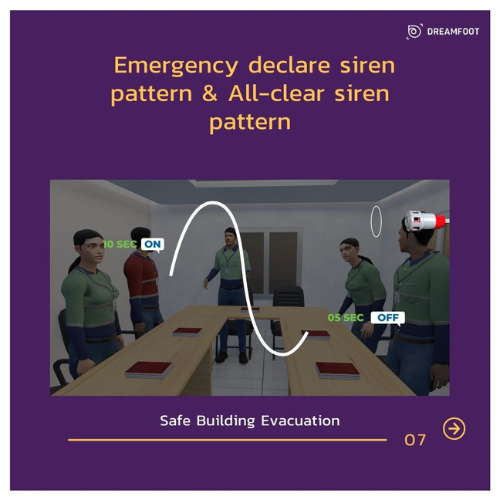

- Correct siren pattern for emergency and clearance

- How to safely resume work after the clearance

Equip Facilities with Necessary Resources

Ensure that industrial facilities are equipped with the necessary resources to facilitate safe evacuation during emergencies.

This includes installing emergency lighting, signage, and communication systems to guide individuals to exits and assembly points. Additionally, provide appropriate personal protective equipment (PPE) and emergency supplies, such as first aid kits and fire extinguishers, throughout the facility.

Specialized Equipment and Resources

Industrial buildings may require the integration of specialized equipment and resources to facilitate effective emergency evacuation. This includes the provision of personal protective equipment (PPE), such as respirators, safety harnesses, and protective clothing, to mitigate hazards specific to industrial operations.

Additionally, consider the availability of emergency response teams trained in industrial firefighting, hazardous materials handling, and other specialized skills to respond to emergencies effectively.

Establish Communication Channels

Effective communication is paramount during emergencies to disseminate critical information and instructions to employees and visitors. Establish robust communication channels, including PA systems, emergency notification systems, and designated communication points, to ensure timely and clear communication during evacuation events.

It is also necessary to implement an incident command structure to facilitate organized and efficient emergency response within industrial facilities.

Designate individuals with specific roles and responsibilities, such as incident commanders, safety officers, and communications coordinators, to manage different aspects of the emergency response. Establish clear lines of authority, communication protocols, and decision-making processes to ensure a coordinated and effective response to emergencies.

Coordinate with External Stakeholders

Industrial organizations do not operate in isolation, and effective emergency preparedness requires coordination with external stakeholders, such as local emergency responders and neighboring businesses. Establish communication channels and protocols for collaborating with external entities during emergencies, including mutual aid agreements and emergency response coordination.

Regularly Review and Update Procedures

Emergency preparedness is an ongoing process that requires continuous evaluation and improvement. Regularly review and update evacuation procedures, taking into account feedback, lessons learned from drills or simulations, and changes in the industrial environment.

Ensure that all individuals within the organization are aware of updates and changes to emergency procedures.

Calm Amidst Chaos: How to Respond Effectively During Emergencies

When an emergency strikes, swift and decisive action is paramount to ensure the safety and well-being of individuals within industrial facilities. Effective response during emergencies requires clear communication, rapid decision-making, and coordinated efforts to evacuate all individuals to safety.

Here are the key steps to take during an emergency evacuation in industrial settings:

- Remain calm and composed to facilitate an orderly evacuation. Encourage others to do the same.

- Follow the designated evacuation routes and assembly points as instructed in the organization’s emergency preparedness plan.

- Do not deviate from the established procedures unless directed to do so by authorized personnel.

- Do not use elevators. Only use stairwells and exits designated for evacuation purposes.

- Offer assistance to those in need, but prioritize your own safety and evacuation.

- In the event of a fire or smoke-filled environment, stay low to the ground where the air is clearer. Crawl if necessary to avoid inhaling smoke or toxic fumes. Cover your nose and mouth with a cloth or piece of clothing to filter out particulates.

- Maintain open communication with fellow evacuees and follow the instructions of designated personnel, such as floor wardens or emergency response teams.

- Coordinate efforts to ensure a smooth and orderly evacuation process, and report any hazards or incidents encountered during evacuation to appropriate authorities.

- Once safely evacuated from the building, proceed to designated assembly points outside the facility. These assembly points serve as gathering areas where individuals can be accounted for and receive further instructions from emergency responders.

- Do not re-enter the building until authorized to do so by emergency personnel.

- Assemble at the designated assembly points and assist in accounting for all personnel and visitors evacuated from the building.

- If not already done so, contact emergency services, such as the fire department or paramedics, to report the emergency and provide relevant details, such as the nature of the emergency and the location of the incident.

- Follow the instructions of emergency responders and await further guidance before returning to the premises.

Rebuilding Trust: Managing Post-Evacuation Procedures and Reputation

In an industrial emergency, your top priority is getting everyone out safely, but what happens afterward is just as crucial. Once you’ve made sure everyone’s out, double-check to ensure nobody got left behind. Then, keep everyone in the loop with clear, timely updates through different channels, so there’s no confusion.

Work closely with emergency responders to make sure they have what they need to do their job effectively. Once things settle down, jump into action to get things back to normal as quickly as possible.

Sit down with the team to chat about what went well and what you can improve for next time. And when it comes to your reputation, be upfront about any impacts and make sure to set the record straight if there’s any misinformation floating around.

Acknowledge the potential impact of the emergency on the organization’s reputation and take proactive measures to manage and mitigate any negative perceptions or fallout. Communicate openly and transparently with stakeholders, addressing concerns and demonstrating a commitment to safety and accountability. Highlight the organization’s swift and decisive response to the emergency, as well as any measures taken to prevent similar incidents in the future.

Develop a comprehensive media and public relations strategy to manage the organization’s reputation in the aftermath of the emergency. Work with communications professionals to craft messaging that is clear, concise, and empathetic, emphasizing the organization’s commitment to safety, integrity, and responsible stewardship.

In the long run, it’s all about building trust with your community and showing that you’re committed to doing the right thing. That way, if anything ever happens again, you’ll be ready, and your reputation will stay strong.

Safety First: Mastering Emergency Evacuation in Industrial Environments

As leaders and decision-makers within industrial organizations, the responsibility falls upon you to ensure the effectiveness of emergency preparedness efforts and to safeguard the reputation and integrity of your organization.

By investing in robust emergency evacuation procedures, proactive reputation management strategies, and a culture of safety and accountability, you can strengthen the resilience of your organization and earn the trust and confidence of stakeholders.

Are you ready to take your organization’s emergency preparedness to the next level?

Contact us to create visual aids like 3D animated safety induction videos to demonstrate the evacuation procedures to your workforce.

Together, let’s ensure the safety and well-being of all individuals within industrial facilities and uphold the reputation and integrity of your organization.