Beyond the Belt: Safeguarding Workers in the World of Conveyor Systems

Belt conveyors stand as the workhorses of modern industry, silently facilitating the movement of goods and materials across vast distances. These mechanical marvels have revolutionized logistics, streamlining processes and enhancing efficiency in countless industries worldwide.

In manufacturing plants, belt conveyors seamlessly integrate into assembly lines to expedite production. In mining operations, these conveyors serve as the arteries of material transport, ferrying ore from excavation sites to processing facilities. Even in the realm of logistics, belt conveyors reign supreme, orchestrating the seamless flow of packages and parcels through sprawling distribution centers.

Yet, amidst their remarkable utility, lurks an inherent risk – one that demands meticulous attention and proactive measures: safety.

In this blog, we unravel the complexities of belt conveyor safety, dissecting the hazards, regulations, and best practices that underpin a secure operational environment. Start your conveyor safety journey with a comprehensive safety induction tailored to the specific needs of your organization.

Understanding Belt Conveyor Hazards

As indispensable as they are, belt conveyors harbor inherent hazards that demand vigilance and proactive measures to mitigate risks. Understanding these hazards is paramount to fostering a culture of safety within industrial environments.

Let’s delve into some of the most prevalent dangers associated with belt conveyors:

| Hazard Type | How it Happens | Risks Involved | Preventive Measures |

| Pinch Points | Moving parts such as pulleys, rollers, and conveyor belts intersect or come close together to create pinch points | Trapping or crushing workers’ limbs or clothing, leading to severe injuries or even fatalities | Identify and safeguard pinch pointsUse appropriate guarding and warning signage |

| Entanglement | Loose clothing, jewelry, or body parts can become stuck during the continuous movement of the belt | Traumatic injuries, amputations, or strangulation | Implement strict dress code policiesInstall guardsProvide training on safe work practices |

| Material Spillage | Improper loading, belt misalignment, or excessive material buildup | Slip, trip, and fall risks for workers | Employ proper containment measuresSecure loads with restraintsProper training in loading techniques |

These hazards merely scratch the surface of the multifaceted risks inherent in belt conveyor operations. From electrical hazards to fire risks, the intricate interplay of machinery, materials, and human factors demands comprehensive risk assessment and mitigation strategies.

Belt Conveyor Safety Standards and Regulations

In the dynamic realm of industrial safety, adherence to stringent standards and regulations is paramount to ensuring the well-being of workers and the integrity of operations.

Belt conveyor systems are no exception. They too are subject to a myriad of regulations and guidelines aimed at safeguarding personnel and optimizing operational safety.

Let’s explore some of the key safety standards and regulations governing the design, installation, operation, and maintenance of belt conveyors:

- Indian Standard (IS) 8598:1998: This standard, titled “Code of Practice for Selection and Design of Belt Conveyors,” provides guidelines for the selection, design, and construction of belt conveyors in various industries. It covers aspects such as conveyor design criteria, belt selection, conveyor components, and safety considerations.

- Indian Standard (IS) 7155:1986: Titled “Code of recommended practice for conveyor safety,” this standard outlines recommended practices for the safe operation and maintenance of conveyor systems. It covers topics such as safety precautions, guarding requirements, emergency stop devices, and training for conveyor operators.

- The Mines Act, 1952: The Mines Act regulates safety and health standards in mines across India. Under this legislation, specific provisions pertain to the safe operation of conveyor systems in mining environments.

- Occupational Safety and Health Administration (OSHA) Legislation: While not specific to belt conveyors, employers are required to adhere to applicable OSHA legislation and implement measures to safeguard workers from hazards associated with belt conveyor operations.

By adhering to these standards and regulations, stakeholders can establish a robust framework for belt conveyor safety, fostering a culture of compliance and continuous improvement.

Additionally, consulting with relevant regulatory authorities and industry experts can provide further guidance on adhering to safety requirements specific to belt conveyor operations in India.

Comprehensive Approach to Belt Conveyor Safety

Ensuring the safety of workers around belt conveyors demands a multi-faceted approach that encompasses the deployment of safety equipment, comprehensive training, and effective emergency preparedness.

By integrating these elements into a cohesive safety framework, organizations can create a robust safety culture and mitigate the risk of accidents and injuries.

Here’s how each component contributes to belt conveyor safety:

1. Safety Equipment and Devices

Implementing a range of safety equipment and devices is crucial for enhancing belt conveyor safety.

Some of the necessary safety devices associated with belt conveyors are:

- Emergency Stop Switches: They enable rapid shutdown in response to hazards such as entanglement, material spillage, or equipment malfunction.

- Guardrails and Barriers: Installed along conveyor pathways and access points, these protective barriers help prevent unauthorized access and shield personnel from pinch points, falling objects, and other hazards.

- Pull Cord Switches: Activated by pulling a cord or cable located along the conveyor’s length, these switches offer a convenient means for workers to initiate emergency stops from various locations along the conveyor line.

- Safety Nets and Screens: Installed beneath conveyor belts or in overhead conveyor configurations, safety nets and screens help mitigate the risk of injury from falling materials or equipment.

- Motion Sensors and Alarms: Motion sensors and alarms provide real-time monitoring of conveyor operation, detecting abnormal movements or deviations from predefined parameters. When triggered by irregularities such as excessive belt speed, misalignment, or material buildup, these sensors activate audible or visual alarms to alert operators and prompt corrective action.

- Anti-static Devices: In environments where flammable materials or combustible dusts are present, anti-static devices help mitigate the risk of static electricity buildup on conveyor belts and components.

- Safety Communication, Signage, and Labels: From warning signs indicating pinch points to instructional labels for emergency stop switches, effective signage enhances situational awareness and promotes safe work practices.

By strategically deploying these safety measures along conveyor systems, organizations create multiple layers of protection to safeguard personnel and equipment.

2. Comprehensive Training and Education:

Equipping workers with the knowledge and skills to operate and work near belt conveyors is paramount.

Workers must be trained to operate conveyor systems in accordance with established protocols, including proper start-up and shutdown procedures, load handling techniques, and safe clearance practices. Workers must understand the importance of wearing appropriate PPE, adhering to safety protocols, and responding effectively to emergencies.

Here are some SOPs to remember while working near conveyor belts:

| Dos | Don’ts |

| Wear appropriate PPE such as safety glasses, hard hats, hearing protection, and steel-toed boots | Don’t attempt to clear obstructions from conveyor systems while they are in operation |

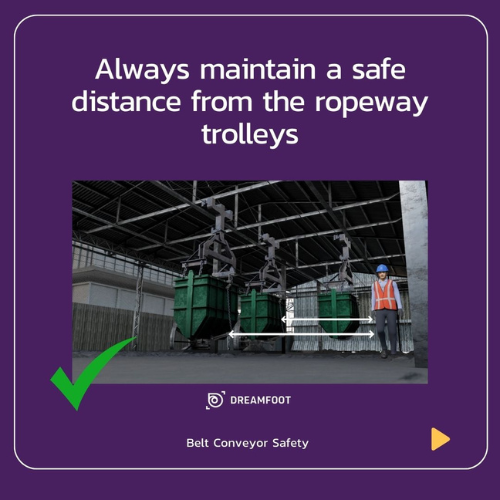

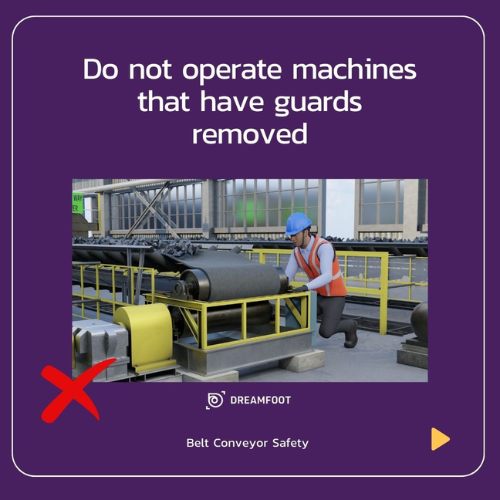

| Always maintain a safe distance moving conveyor components, such as belts, pulleys, and rollers, to avoid pinch points and entanglement hazards | Do not bypass or disable safety devices such as emergency stop switches or guards |

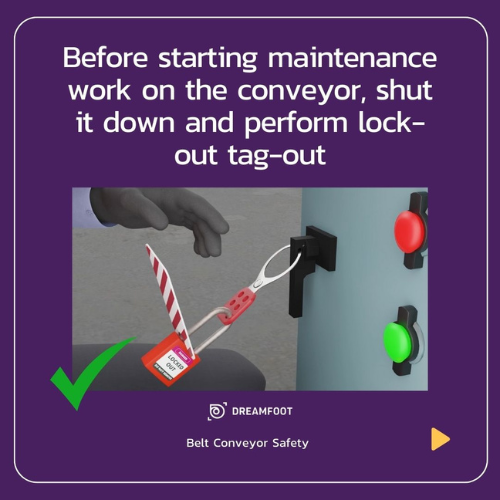

| Follow lockout/tagout procedures when performing maintenance or servicing tasks on conveyor systems | Don’t overload conveyor systems beyond their designed capacity |

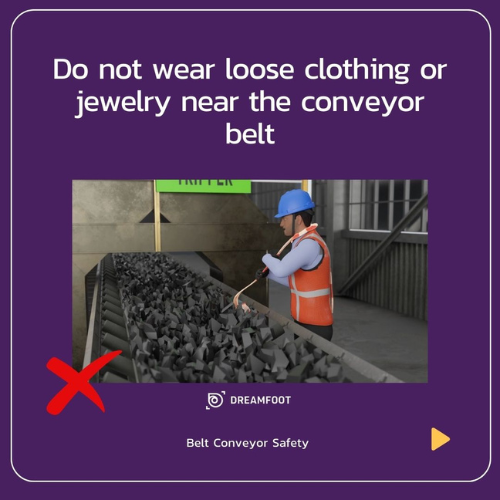

| Conduct routine inspections of conveyor systems to identify signs of wear, damage, or malfunction that could pose safety hazards | Don’t wear loose clothing, jewelry, or accessories that could become caught in conveyor machinery |

| Maintain a clean and organized work environment to prevent trip hazards and material spillage | Don’t ignore warning signs and respond promptly to alerts |

| Pay attention to safety signs and labels posted near conveyor systems | Do not stand or walk on conveyor belts |

| Report any safety concerns or hazards observed near conveyor systems to supervisors or safety personnel | Never attempt to repair or modify equipment without proper training and authorization. |

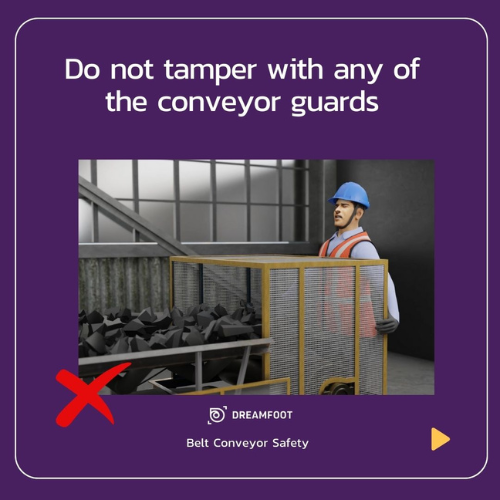

| In case of an emergency, use the pull cord switch to stop the conveyor | Do not tamper with any of the conveyor guards or enter a machine that has guards removed |

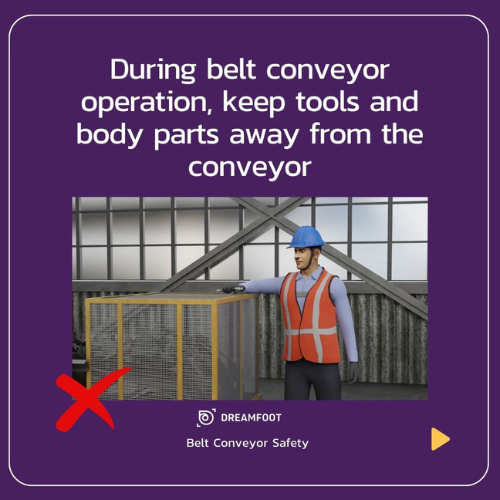

| Always ensure tools are kept away from the moving conveyors | Never enter a confined space like a bunker without the necessary permit |

Ongoing education and refresher training ensure that workers remain vigilant and prepared to handle evolving safety challenges.

The best way to educate workers about safety is via 3d animated SOP videos. The engaging safety animations and audio-visual learning videos help workers quickly understand the procedures required to keep themselves and others around them safe.

3. Effective Emergency Preparedness

Preparedness for emergencies is essential for minimizing the impact of unforeseen incidents such as conveyor belt fires, equipment breakdowns, or personnel injuries.

Organizations must develop and implement effective emergency response plans that outline procedures for evacuating personnel, activating emergency stop switches, and summoning assistance. Regular drills and simulations reinforce emergency protocols and ensure that workers can respond calmly and decisively in high-pressure situations.

In the dynamic realm of industrial operations, safety is not just a priority – it’s a responsibility shared by every member of the organization. Investing in these foundational elements of conveyor belt safety demonstrates a commitment to prioritizing safety and fostering a secure working environment for all.

Explore our comprehensive emergency preparedness blog for valuable insights and strategies to enhance your organization’s hazard communication and safety protocols.

The Imperative of Continuous Improvement in Belt Conveyor Safety

When it comes to safety, complacency is not an option. Belt conveyor systems, as vital arteries of industrial operations, and so, demand relentless vigilance and a commitment to continuous improvement.

By embracing a culture of continuous improvement, organizations can proactively identify and address emerging risks and hazards, ensuring the ongoing safety and resilience of their conveyor systems.

Below are some of the steps organizations can take to promote safety within their premises:

- Leverage technologies such as sensors, data analytics, and predictive maintenance tools to monitor key performance indicators and detect potential issues before they escalate into safety hazards

- Perform periodic evaluation of safety protocols, procedures, and equipment to identify areas for improvement and optimize safety performance

- Conduct regular safety audits, risk assessments, and incident investigations to gain insights into potential vulnerabilities

- Collect feedback from workers and stakeholders, to gain a comprehensive understanding of safety challenges and develop targeted solutions

- Implement corrective actions, whether through engineering controls, administrative measures, or behavioral interventions, thus addressing identified hazards and improving safety outcomes

- Encourage workers to share insights, ideas, and best practices for enhancing belt conveyor safety

- Establish channels for open communication, knowledge sharing, and collaboration

Continuous improvement is the lifeblood of belt conveyor safety, driving organizations to strive for excellence and adaptability in the face of evolving challenges.

Protecting Workers Around Belt Conveyors in Industrial Settings

As stewards of safety within industrial environments, the responsibility lies with you to prioritize the wellbeing of your workforce and uphold the integrity of your organization.

By implementing comprehensive safety measures, investing in ongoing training, and fostering a culture of safety and accountability, you can fortify your organization against potential risks and demonstrate your commitment to workplace safety.

Are you ready to elevate your belt conveyor safety practices to the next level?

Reach out to our team to learn more about our audio-visual safety video training solutions and how we can partner with you to enhance belt conveyor safety in your organization. Together, let’s pave the way towards a safer, more resilient future.